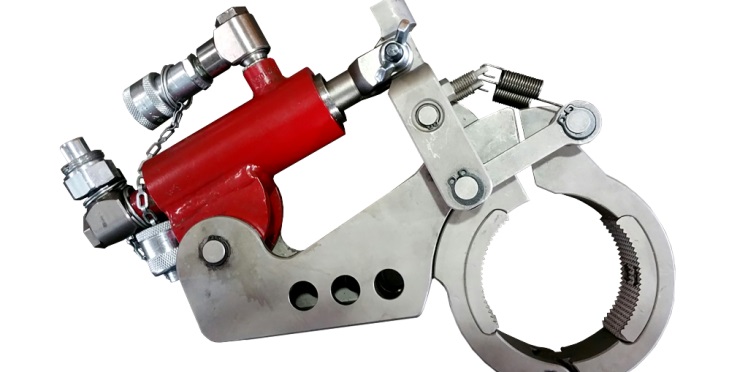

Bolt Torquing and Tensioning:

Our technicians can perform these tasks for you on your site. We have qualified personnel with many years of experience and operate according to the required quality specifications and safety rules on site. The number one cause of leaks is flanges, although they are not designed to leak. Flanges leak due to incorrect assembly and inaccurate bolt loads. Using hydraulic bolt torques or tensioners, we provide controlled bolt tensioning services to ensure your flanges will not leak, enhancing system integrity, safety and reducing costly unscheduled downtime. To prevent leakages, we offer our customers a total package of services. We check the surface of the flange, machining where necessary, deliver the right gaskets and bolts and closing the flange connection with the correct calculated bolt strength.

For a Startup, Commissioning, T&I, Turnaround or a Shutdown, Bolting is an essential part of the Mechanical Maintenance activities. The Maintenance starts and ends with Bolting & Inspection. Tritorc provides total solution for all your bolting requirements, including Torqueing, Tensioning, Stress Analysis, Flange Management, and more. With an in-house capability.