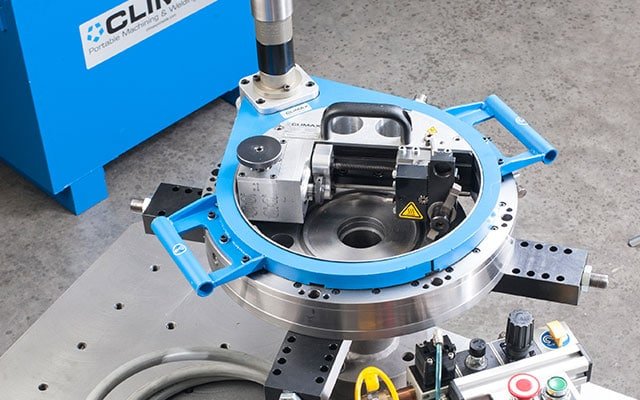

Operation:

The most common types of seals are found on RF (Raised face) flanges with phonographic grooving and spiro-metallic gasket, RTJ (Ring Type Joint), with trapezoidal section circular groove, flat flanges with seats for O-rings, or other types of annular gaskets. In each of the cases mentioned above, a particular mechanical machining of leveling and profiling of sealing area is required.

Working Range:

Up to Ø3000 (120 inches) in facing and around 100mm in boring.

Flange facing is one of the most important repair jobs during plant shutdowns or maintenance. And we provide the following flange facing services:

- Re-facing of main inlet steam flanges

- Repairing heat exchanger nozzle flange

- For sealing and weld prep, facing and bevelling of the pipe are required

- Repairing flat face raised face and phonographic finish flanges

- Repairing piston rod mating flanges

- Boiler feed pump flanges

- Re-machining the gasket seal on tube sheets

- Cutting new grooves or fixing ring grooves

- Vessel and plate weld prep

- Re-facing ship hatch sealing surfaces

- Re-machining bearing surface of rotary cranes

- Resurfacing large pump base housings

- Re-facing valve flanges and repairing heat exchangers

- Flange milling wind tower section

- Ship thruster mount facing, drilling, and milling